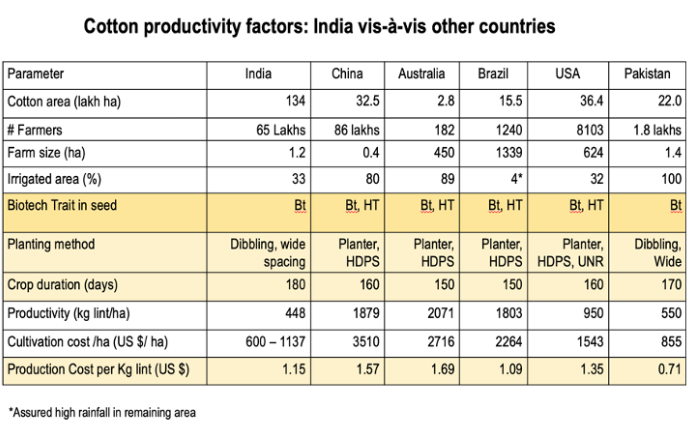

In India, cotton is normally cultivated in over 128 lakh ha area spread across three geographical regions: North (13% area across Punjab, Haryana and Rajasthan), Central (76% area across Gujarat, Madhya Pradesh, Maharashtra and Odisha) and South (27% area across Telangana, Andhra Pradesh, Karnataka and Tamil Nadu). More than 95% area is under Genetically Modified Cotton (transgenic Bt cotton, two genes cry1Ac and cry2Ab from a bacterium, Bacillus thuringiensis). Cotton production stood at 337 lakh bales (lint yield, 170 kg each bale) during 2022-23 season with a productivity of 445 kg lint/ha, which is much lower than that achieved in other cotton growing countries. A look into the area spread and productivity of Cotton at the district level perhaps can help understand the constraints to higher productivity at the district level. Cotton is cultivated in about 240 districts spread across 11 states but 157 of these districts have an area more than 10000 ha. More than 60% cotton is rain dependent and subjected to the vagaries of the south west monsoon. In 42 districts, cotton production is considered as efficient in over 24 lakh ha (19% area) with an average productivity of 625 kg lint/ha In 75 districts it is considered less efficient spread across 90 lakh ha (75% area) with an average productivity of 350 kg lint/ha In 40 districts, cotton production is considered inefficient spread across 7.5 lakh ha (5.5% area) with an average productivity of <335 kg/lint/ha

HDPS - a global best practice

High density planting system (HDPS) is widely adopted in cotton growing countries with significantly higher productivity. In India, cotton is grown under hybrids at a low seed rate at a wider spacing resulting in low plant population. Elsewhere emphasis is on productivity per unit area rather than per plant as in India. Also HDPS cotton is grown under irrigated or assured rainfall conditions. Crop duration is invariably 150- 160 days and mostly machine harvested and processed. Higher cultivation cost is incurred but due to higher productivity, production per kg lint is comparable or only marginally higher. HDPS cotton - a widely adopted global best practice

What is HDPS cotton

In other countries adopting HDPS, very high seed rate of variety is used (12-15 kg/ha) at a higher density resulting in plant population of over 1,11,000 plants/ha. Conventionally In India, hybrids seeds are planted at a seed rate of 2 packets (450g each of Bt cotton seed) at a spacing of 90 cm row to row and 60 cm plant to plant spacing per acre resulting in a plant population of 7400 plants/acre. In HDPS, higher seed rate (5-6 seed packets/ac) is used for sowing at a spacing of 90 x 15 cm resulting in a plant population of 29000 plants/acre (4 times more population than a conventional spacing). Early to medium maturing, compact hybrids are used in HDPS rather than hybrids which are bushy and are of longer duration (170-180 days). HDPS is best suited to shallow to medium soils where currently the productivity is low (<350 kg lint/ha). Canopy management with sprays of plant growth regulator chemicals to render the plants compact under rainfed conditions is essential so that plants have reduced internodal distance and height. Each plant is expected to bear 8-12 bolls per plant and mature synchronously. Cotton is harvested in one-two pickings. With the use of defoliant at 70% bursting, HDPS planted cotton is amenable for machine picking as practiced in other countries. Currently farmers spend 32% of labour cost on manual picking of cotton. Contamination during harvesting, storage and transport to the cotton gin is a bottleneck for realising quality cotton.

Challenges for adoption

1 Availability of seed and cost of suitable hybrids/ varieties 2 Timely availability of pneumatic planters for precision planting or higher labour requirement for manual sowing at higher seed rate 3 Weed management manually within rows or through herbicide use (pre- and post- emergence herbicides) 4 Canopy management spray decisions more complicated by prevailing moisture limiting conditions under rainfed situation in comparison to irrigated situation

Advantages

1 Productivity enhancement by 30-60% in shallow soils 2 Crop escapes boll damage from the late season pest, pink bollworm 3 Early termination of crop and higher returns 4 Amenable for machine harvesting, reduction in contamination level

Field roll out of HDPS cotton demonstrations

A special project on cotton is currently underway funded by the Ministry of Agriculture and Farmers Welfare and implemented by ICAR-CICR, Nagpur in 8 States across 57 districts, 286 clusters covering more than 9000 ha area and 10000 farmer beneficiaries. HDPS technology intervention is being demonstrated in over 3500 ha in 6 states through public-private partnership mode involving both the Ministries (Ministry of Agriculture and Ministry of Textiles), ICAR-CICR, Textile Industry Associations (CITI and SIMA), Seed Associations (FSII and NSAI), Seed firms (RASI, Nuzuveedu, Crystal, Rallis, Mahyco, Bioseed, Kaveri, Ankur etc), ATARIs & Krishi Vigyan Kendras (KVKs), State Department of Agriculture & CCI. Technology assistance is being provided to farmers through Direct Benefit Transfer.

Y G Prasad

Director, ICAR-Central Institute for Cotton Research, Nagpur